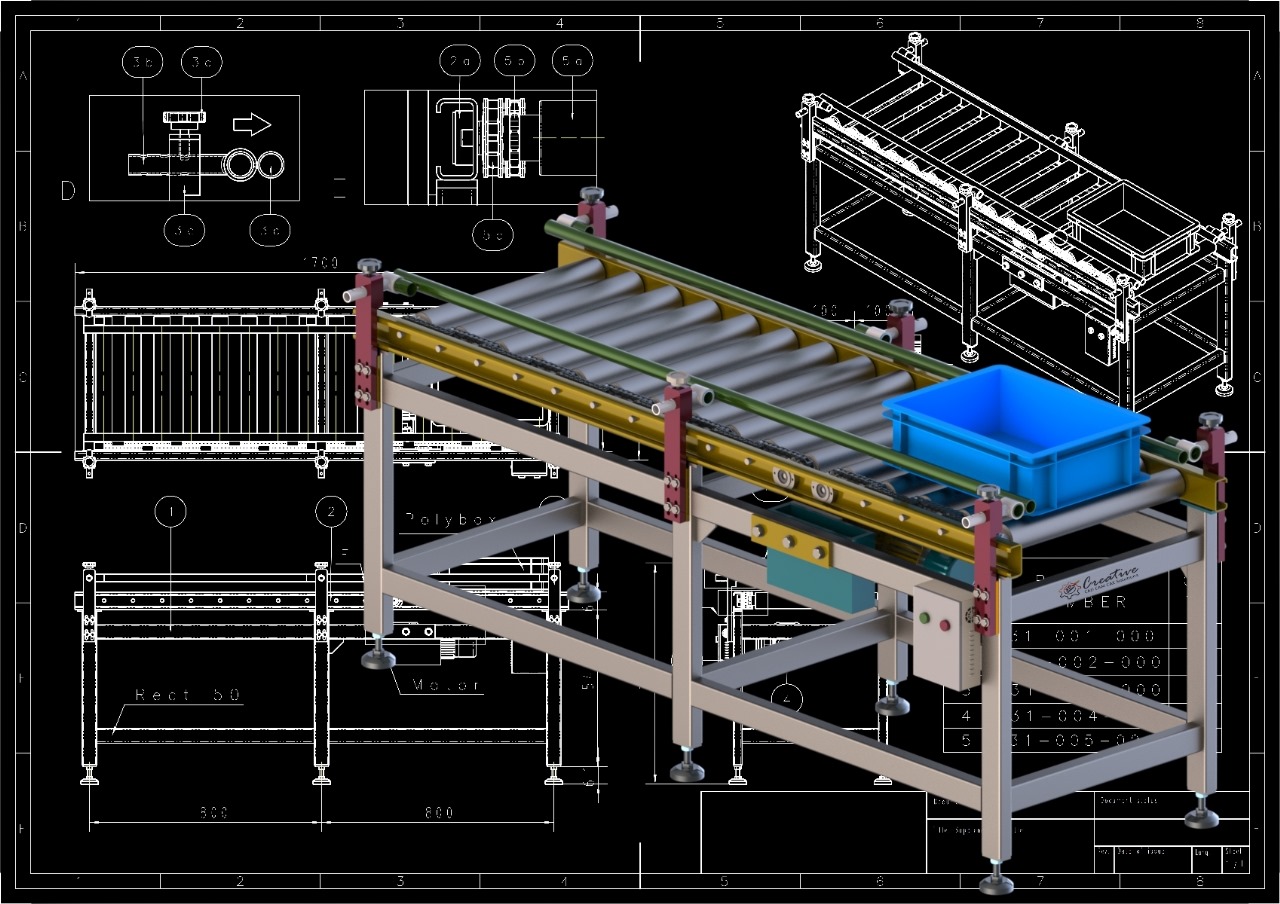

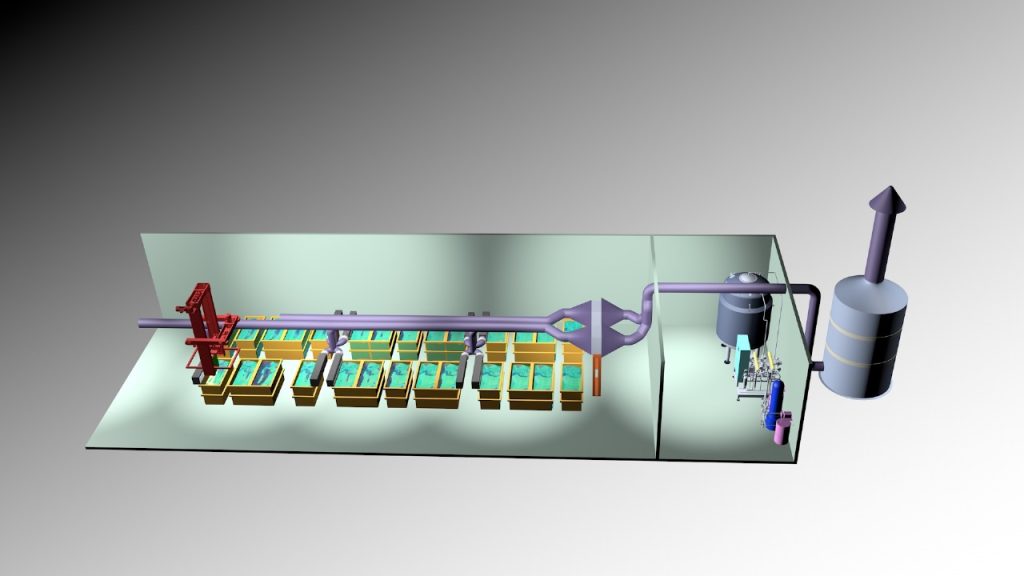

Our team develops mechanical systems to meet specific industrial needs, offering comprehensive design solutions from conceptualization to optimization.

Machinery Engineering Design solution

Our team of Engineer offer several industrial solutions to equipment that incorporate various types of equipment to achieve specific objectives or functionalities. This can apply to a wide range of industries and applications, including manufacturing, transportation, energy production, healthcare, telecommunications, and more

Machinery Engineering Design solution

Machinery engineering design involves the creation and development of mechanical systems, equipment, and machinery solutions to meet specific industrial, commercial, or consumer needs.

- Conceptualization

- Detailed Design

- Prototyping

- Optimization

- Manufacturing Support

Steps

The first step in equipment system design is to

understand the requirements and objectives of the system. This may involve

consultation with stakeholders, conducting needs assessments, and defining

performance criteria, functionality, capacity, and constraints.

Based on the requirements analysis, conceptual design

involves developing initial concepts and ideas for the equipment system. This

may include defining the overall system architecture, selecting appropriate

equipment types, and determining how they will be integrated and configured

to meet the desired objectives.

Once the conceptual design is established, the next step is

to develop detailed designs for each component of the system. This involves

specifying the specifications, dimensions, materials, and other parameters for

each piece of equipment. It may also include designing interfaces,

connections, controls, and safety features.

Equipment system design requires selecting the

right equipment for the intended application. This involves evaluating

different options based on factors such as performance, reliability, cost,

compatibility, scalability, and ease of maintenance. Equipment selection may

involve collaboration with suppliers, manufacturers, and specialists in the

field.

In equipment system design, it’s crucial to

ensure that all components work together seamlessly. This involves designing

interfaces and connections between different pieces of equipment, as well as

integrating control systems, communication protocols, and data exchange

mechanisms

Equipment system design must consider safety

regulations, standards, and compliance requirements applicable to the

industry and application. This includes designing safety features,

implementing risk assessments, and ensuring that the system meets all

relevant regulatory requirements.

Before deployment, equipment systems undergo

testing and validation to ensure that they meet performance specifications,

functionality requirements, and safety standards. This may involve prototype

testing, simulation studies, and functional testing under various operating

conditions.

Equipment system design involves creating

documentation, manuals, and user guides to support installation, operation,

maintenance, and troubleshooting of the system. This documentation

provides essential information for users, technicians, and maintenance

personnel.

Equipment system design considers the entire

lifecycle of the system, including factors such as durability, reliability,

maintainability, and sustainability. Design decisions may impact the system’s

long-term performance, cost-effectiveness, and environmental footprint.

FAQ

Conceptualization: Initial brainstorming and ideation of design concepts based on functional requirements.

Detailed Design: CAD modeling, structural analysis, and component selection to create detailed plans.

Prototyping: Building and testing prototypes to validate design concepts and functionality.

Optimization: Iterative refinement of designs based on testing, analysis, and feedback.

Manufacturing Integration: Collaboration with manufacturing teams to ensure designs are producible and scalable.

Machinery engineering design optimizes mechanical systems to operate efficiently under specific conditions, minimizing energy consumption and maximizing output.

Through rigorous testing and analysis, design flaws are identified early, enhancing reliability and reducing the risk of failures or downtime.

Machinery engineering design solutions are essential across various industries such as manufacturing, automotive, aerospace, agriculture, healthcare, and consumer goods.

These solutions cater to specific industry needs, from precision machinery in manufacturing to complex systems in aerospace, ensuring tailored designs that meet performance, safety, and regulatory standards.