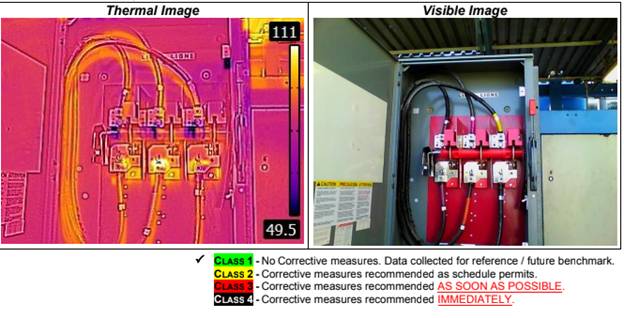

At LeanX, our experts use advanced infrared cameras to detect temperature variations and identify anomalies, ensuring efficient and safe operations

Infrared Thermography

Infrared thermography, also known as thermal imaging, is a technology that captures and visualizes the infrared radiation emitted by objects. Every object with a temperature above absolute zero emits infrared radiation, which is invisible to the human eye. Our Infrared License technician use state of the art technology Infrared cameras to detect radiation and translate it into a visible image, often showing variations in temperature as different colors or shades.

Infrared Thermography

Infrared thermography is a non-destructive testing technique used to detect and visualize thermal patterns emitted by objects and surfaces. It provides insights into temperature variations that can indicate anomalies or defects.

- Non-Destructive Testing

- Detects Temperature Variations

- Visual Thermal Imaging

- Expert Analysis

- Cost Efficiency

- Safety and Compliance

Steps

By identifying temperature variations,

infrared thermography can detect issues such as electrical faults, mechanical

failures, or insulation deficiencies before they escalate into costly problems.

This proactive approach allows for timely maintenance or repairs, reducing

downtime and potential safety hazards.

Unlike traditional methods that require physical

contact with objects or systems, infrared thermography enables remote

inspection without disturbing operations or risking safety. This non-contact

feature is particularly useful in hazardous environments or hard-to-reach

areas.

Infrared thermography enhances safety by allowing

technicians to assess equipment and structures from a distance, reducing the

risk of accidents or injuries associated with manual inspections. Additionally,

early detection of potential hazards such as overheating electrical components

can prevent fires or other catastrophic events.

By pinpointing specific areas of concern, infrared

thermography helps prioritize maintenance efforts and allocate resources

efficiently. This targeted approach can lead to significant cost savings by

preventing unnecessary repairs and minimizing downtime.

In building inspections, infrared

thermography can identify areas of heat loss or air leakage, enabling property

owners to improve insulation and energy efficiency. By optimizing thermal

performance, businesses and homeowners can reduce energy consumption

and lower utility costs.

In manufacturing processes, infrared thermography

can detect defects or irregularities in products, materials, or components by

analyzing temperature variations. This quality control measure ensures

product integrity and compliance with industry standards.

FAQ

Infrared thermography is a technology that uses infrared cameras to detect and visualize thermal patterns emitted by objects and surfaces. It translates infrared radiation into visual thermal images, revealing temperature variations that can indicate issues like electrical faults, mechanical wear, or insulation deficiencies.

Infrared thermography is important because it enables early detection of potential problems that may lead to equipment failures or structural issues. By identifying temperature anomalies, it allows for proactive maintenance, reduces downtime, optimizes energy efficiency, and enhances safety in industrial and building environments.

Infrared thermography works by capturing infrared radiation emitted from objects and converting it into a visual thermal image. These images display temperature variations as different colors or shades, which thermographers analyze to assess the condition of equipment or structures. By interpreting thermal patterns, experts can identify areas of concern and recommend appropriate maintenance actions to prevent failures and ensure operational reliability.